Blow - moulding machines

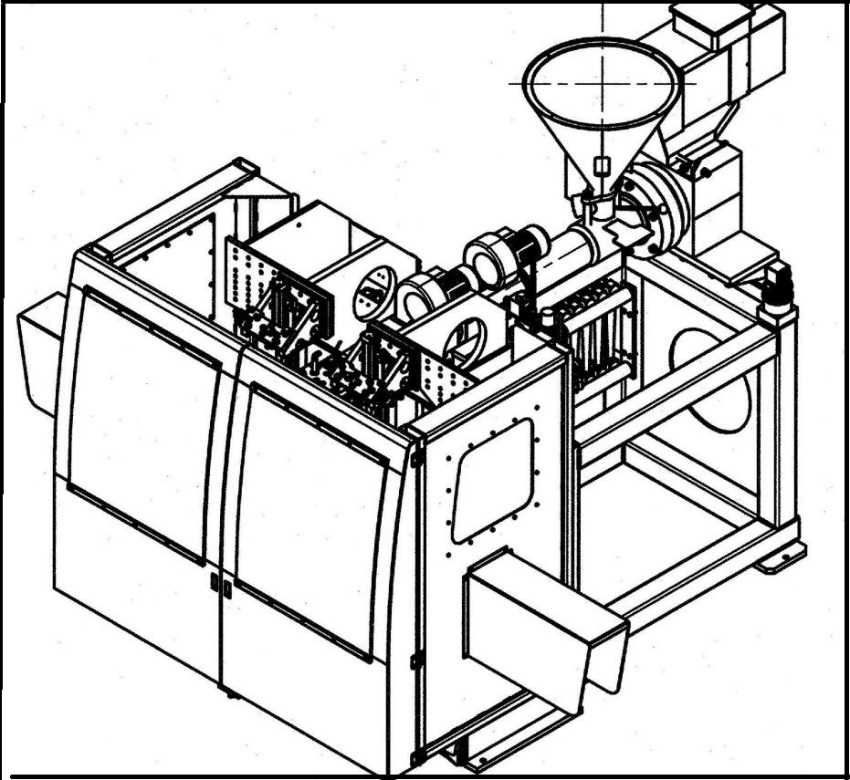

CHODOS CHODOV s.r.o. is a historical producer of blow-moulding machines designed for production of hollow bodies with various nominal volumes. On blow-moulding machines, thermoplastic of PE-LD, PE-HD, PVC-U, PP and in some cases also PET-G may be processed. The blow-moulding machines dispose of an all-welded massive and rigid frame, ensuring a high accuracy of inserting the thorn into the mould and a precise adjustment of partition plane of the mould thanks to a double synchronization of mould closing. The blow-moulding machine consists of extruding machine, blow-moulding unit, hydraulic system, pneumatic system and control part. The machines are designed in one- or two-mould variants. The blow-moulding is realized from upwards, the movement of mould carriage is horizontal.

BLOW-MOULDING MACHINE VA 521 TYP 033 015 M001

In 2017, we manufactured VA 521, which is the first one from the new series of blow-moulding machines.

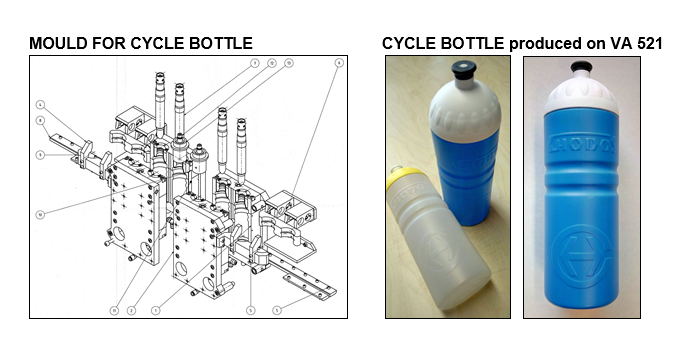

The blow-moulding machine 521 is an up-to-date, efficient, two-mould machine designed for blow-moulding of hollow bodies with nominal volume 1 liter. The specific production possibility depends on dimension of clamping surfaces of the mould. We offer the machine in conformity with up-to-date trends in electrical or hydraulic–electrical design. In its basic version, the blow-moulding machine is equipped with a wall thickness regulation and according to processed material, with a corresponding screw and extruding head.

Machine equipment – periphery upon the customer wish:

- trimming of feeding head for production of wide-neck containers

- pellet suction device

- dosing / dyeing unit

- cooling aggregate

- conveyors / conveyor belts

- possibly other equipment upon request of customer

For production of smaller amount of products, it is possible to supply this blow-moulding machine in a single-mould version. Within the frame of the new series of blow-moulding machines, our company has been preparing a project for another blow-moulding machine for production of containers with volume of 6 – 10 liters.

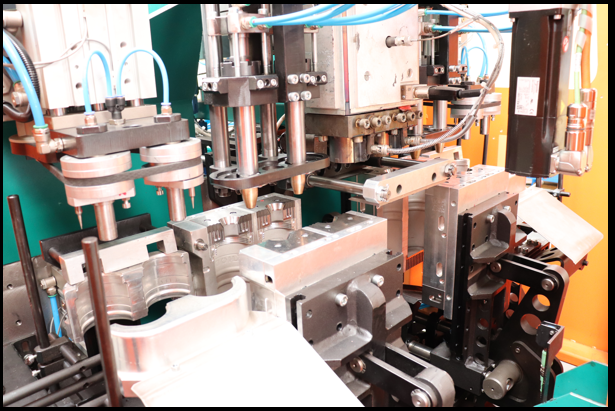

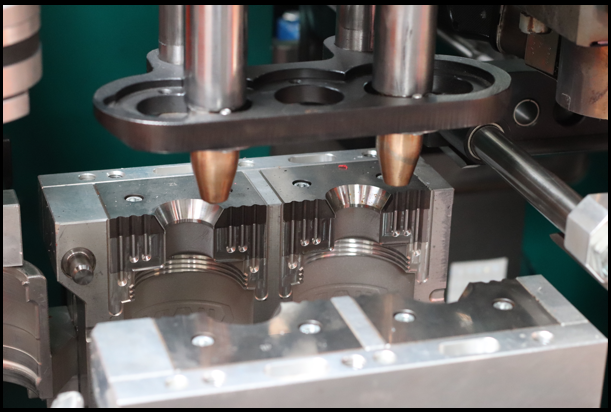

MACHINE DESCRIPTION / PURPOSE

The machine has two moulds, blow-moulding from upwards, and horizontal movement of mould carriage. When separating parison, the extruding machine moves vertically. The mould mechanism is constructed with respect to stability of partition plane by increasing the closing force through a symmetric layout to mould partition plane and loading the guide elements by straight pull. The mould carriage drive and the mould closing are solved according to the machine design either with hydraulic cylinders, where the mechanism are equipped with a continuous position measuring for optimization of movement speed, or by the electromechanical design, the drive is created by a moving screw and an electric motor. The blow-moulding thorns has also got a drive with a moving screw and an electric motor. The entire blow-moulding may be adjusted in two axes in horizontal plane, in case of two-way design, each individual blow-moulding thorn may be also adjusted vertically. In case of three-way blowing, there is a possibility to adjust the individual blow-moulding thorns vertically. The mould as well as thorns are tempered with cooling liquid from water distribution. The overflow separation stations is located behind the blow-moulding station, where the overflow on the hollow body held in the mask is removed with help of a last located on the plate of the piston rod of the pneumatic cylinder with linear guiding. The output of hollow bodies is oriented with help of an output device. The blow-moulding machine has got screw diameter 60 mm and may be alternatively chosen with or without input grooved zone. The front support of the working cylinder ensures the vertical movement of the extruding head when separating parison. The drive is secured alternatively with help of a hydraulic cylinder, pneumatic cylinder, possibly motion screw with electric motor. The height of the entire blow-moulding machine may be adjusted according to the extruding head and the parison separation type. The drive of the extruding unit has got 22 kW A/C. The extruding unit may be alternatively equipped with input, cooled, grooved zone. The hopper may be locked, or drained in case of emergency. The extruding heads may be chosen one-way, two-way or three-way. They may be equipped with a 64-point regulation of parison wall thickness. The parison separation under the extruding head may be side-type, with help of counter-rotating knives or cutting in the middle of parison. The separation with counter-rotating knives may be alternatively equipped with parison welding in its lower part. The hydraulic aggregate and water distribution are located in the rear frame, the individual sections of compressed air distribution are located on the front frame. The covering is made of a welded construction and is equipped with required safety elements. The electric case is positioned on the rear frame. The machine control, except of basic functions, is ensured with help of a 17“ touch display. The machine has got CE marking.

TECHNICAL DATA - MACHINE PARAMETERS:

machine dimensions (VS D60, hopper, motorization)

length...........................................................................3057 mm

width ............................................................................1674 (2859*) mm

height............................................................................2148 mm

weight........................................................................... 3 500 kg (total)

installed power...............................................................60 kVA

nominal power of screw drive........................................ 22 kW

machine dead time...........................................................2 s

pitch by two-way layout.................................................100 mm

pitch by three-way layout...............................................2 x 70 mm

mould opening...............................................................120 mm

mould depth...................................................................2 x 75 mm

maximum mould width....................................................220 mm

maximum mould height..................................................350 mm

clamping plate dimensions.............................................220 x 300 mm

closing force....................................................................40 kN

hydraulic system pressure.............................................. 16 Mpa

* with output cover

MACHINE CONSTRUCTION:

1.) Hydraulic part (hydraulic drive has got mould carriage, mould closing, resp. front

support of working cylinder)...................................................... 033 015 M001

2.) Electromechanical part.............................................................. 033 015 M002

MACHINE EQUIPMENT:

One-way extruding head................................................................ 033015K011

Two-way extruding head................................................................ 033007K117

Three-way extruding head............................................................. 033015K012

Regulation of parison wall thickness.............................................. BA00037001

Accessories.....................................................................................EA00741001

Screw PE-LD.................................................................................... C506693

Screw PE-HD.................................................................................... C506692

Conversion of VS with input grooved zone..................................... CA00118001

Screw PE-LD VDRZ........................................................................ CA00116

Screw PE-HD VDRZ....................................................................... CA00117

Parison separation SS.................................................................... BA00020001

Side parison separation.................................................................. CA00047001

Parison separation in the middle of parison.................................... CA00048001

Tester DP……………………………………...................................... CA00123001

Lost head separation (ZTRH)......................................................... BA00070(1)001

Front support -hydraulic drive...................................................... BA00026001

-pneumatic drive..................................................... CA00187001

-electromechanical drive....................................... CA00217001